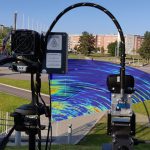

The spectrum of XR from augmented to virtual reality (AR to VR) contains many reference points for use cases inmanufacturing. The benefit of AR is the location specificity of solutions and possibility to enhance the physical environment with data. VR on the other hand can transfer a full production line into virtuality. Enhancing the virtual environment with data allows more intuitive situation awareness for the user. In addition, using immersive VR in this way, as a user interface for teleoperation, can enhance worker and machine safety or improve accessibility of the workplace. The same virtual environment can be as a platform for standalone training simulations, or when connected to the data from physical factory for situation awareness or even two directional teleoperations. To be able to integrate IoT and XR with as low delay as possible and without relying on predictive solutions fast networking with 5G is required.

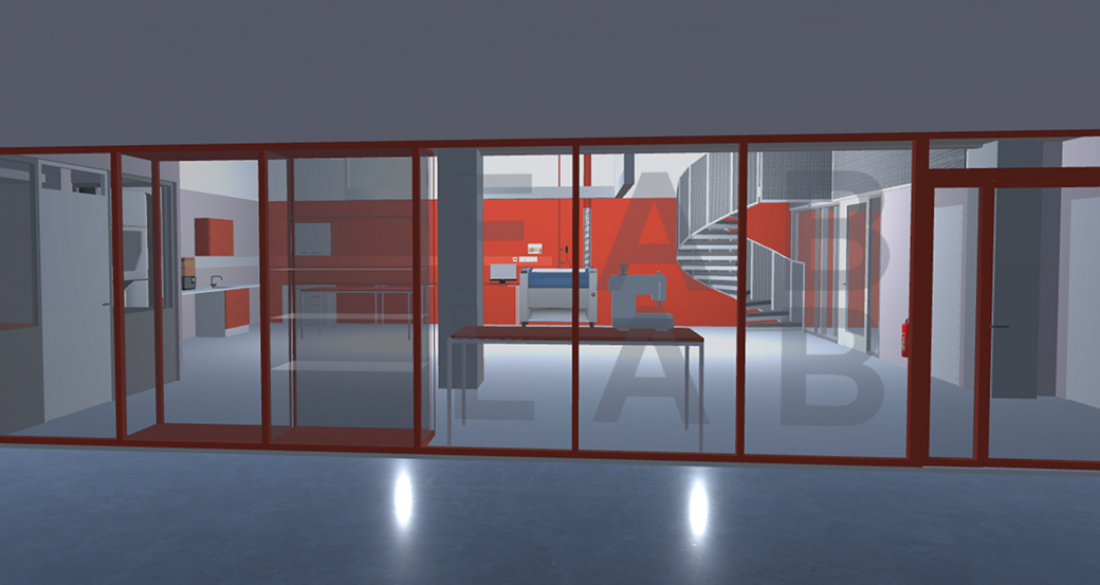

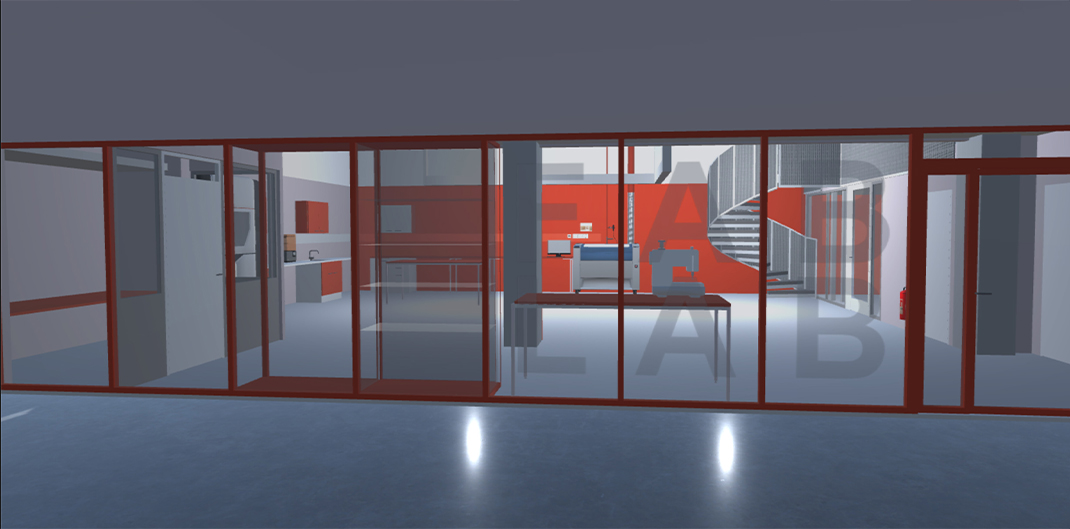

Fig 1. Physical, virtual and VR Fab Labs.

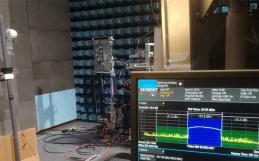

In this use case a building information model of the Fab Lab at the University of Oulu was used to create a visual digital twin and an immersive VR environment for laser cutting. Sensor setup for situation awareness for the laser cutter was planned and an actuator for being able to partially teleoperate the machine was built. This IoT network still requires full integration into the immersive VR, meanwhile the VR environment is being used in safety training for laser cutting and as a basis for future research in finding solutions for XR in teleoperation.

Fig 2. The Fab Lab virtual environment.

For queries please contact:

Adj. Prof. Susanna Pirttikangas

[email protected]

Paula Alavesa

[email protected]